diagnostics & programming

Modern engines rely on sensors and software to run properly. If something’s off, you might notice poor performance, warning lights, or regen issues. That’s where diagnostics and programming come in.

Using advanced diagnostic tools, we scan your engine for fault codes and identify what’s wrong, whether it’s with the turbo, fuel system, EGR, or aftertreatment. From there, we can reprogram components, reset parameters, and update software as needed.

This service is especially important for engines like the Volvo D13 and Cummins ISX. Catching problems early helps prevent breakdowns, improves fuel economy, and keeps you DOT-compliant.

We don’t guess. Our technicians make sure your engine is dialed in and running at its best. Whether you need help with performance, emissions, or drivability, we’ve got you covered.

Note: We only perform internal engine repairs on Volvo D13 and Cummins engines. While we service other trucks, deep engine tear-downs and rebuilds are limited to these two.

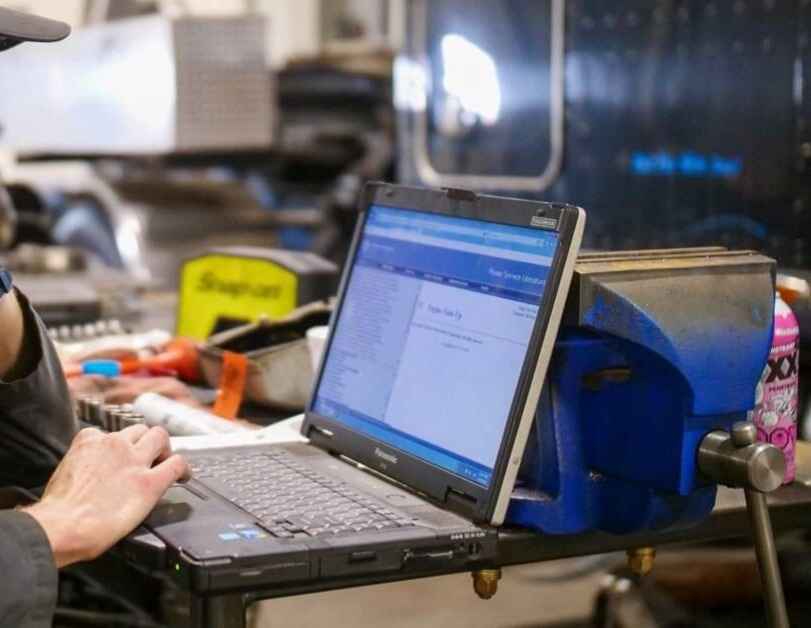

Computer Diagnostics

Full System Scan

We run a full scan using advanced diagnostic tools to detect active and stored fault codes. This gives us a clear picture of what’s going on before we start any repairs.

Sensor calibration

Faulty sensor readings can throw off the whole engine. We test and recalibrate sensors like MAP, MAF, NOx, and exhaust sensors to make sure they’re accurate.

aftertreatment diagnostics

DPF, SCR, and EGR issues are common in modern engines. We diagnose and reset aftertreatment systems to restore proper regen cycles and emission performance.

ECM Programming

Need parameter updates or software calibration? We reprogram ECMs to match factory specs or apply updates required after component replacements.

Forced Regens

If your truck won’t regen on its own, we can trigger a forced regen safely and monitor the process to make sure everything clears out properly.

Idle Shutdown & Speed Settings

We can update idle timers, speed limiters, cruise settings, and other programmable features through the ECM, Customized to how you run your truck.

What You Should Know

What’s Included in an Engine Diagnostic

Reads all major control modules for active and inactive fault codes.

Tracks real-time performance from sensors and modules.

Resets inactive codes after issues are fixed.

Update software or customize engine behavior based on your needs.

When Should You Get Diagnostics Done

Don’t ignore warning signs—scan early to avoid damage.

Performance drops often trace back to engine or sensor issues.

Make sure parts are working correctly and calibrated.

Catch hidden issues before they turn into costly repairs.

Why It Matters

Early detection means less time off the road.

Restores lost power, torque, and efficiency.

Avoid fines and keep your truck legal and clean.

Fixing small issues now prevents bigger ones later.