Fuel System Repairs

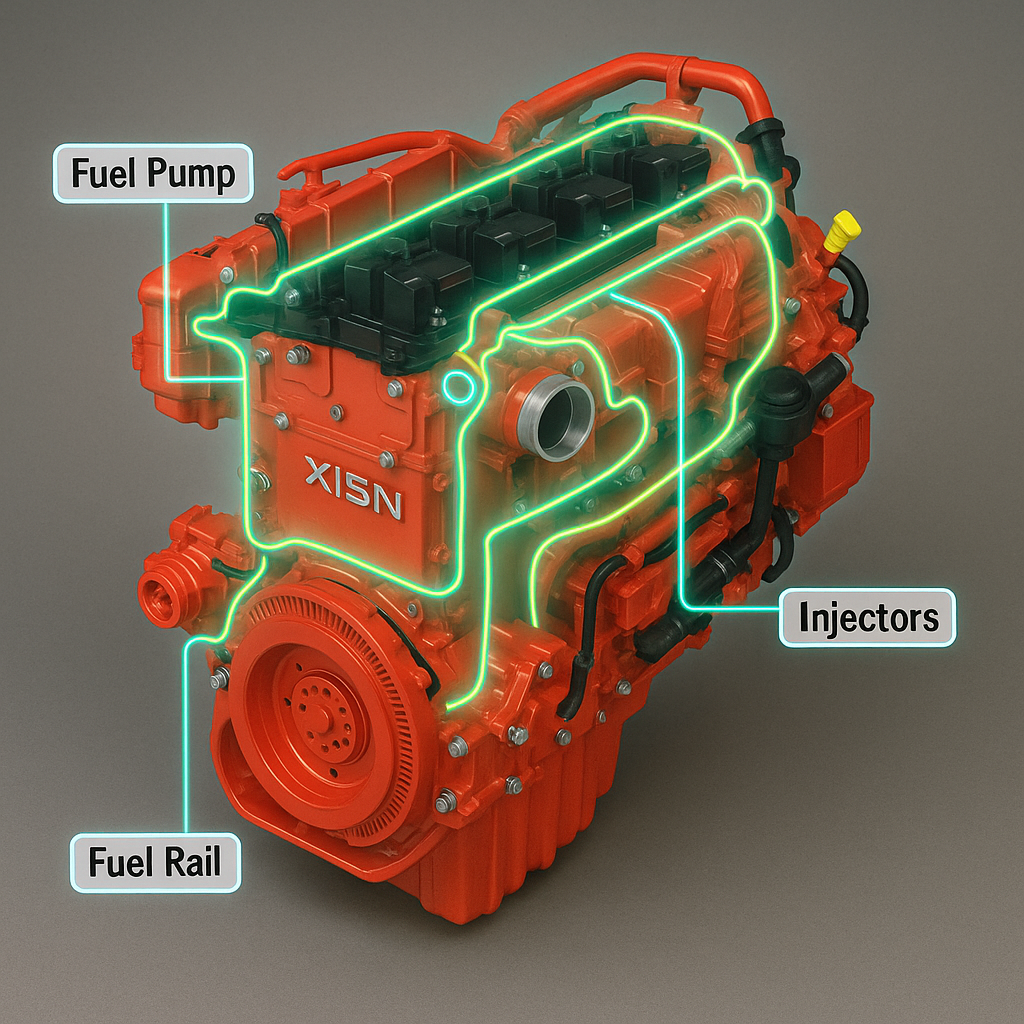

Your fuel system must deliver clean fuel at the right pressure. When it’s dirty, leaking, or weak, you lose power and burn more. Left alone, it can wash cylinders, clog the DPF, and hurt the pump or injectors.

Watch for this. Slow pull. Long crank. Rough idle. Black or white smoke. Strong diesel smell. Poor MPG. Air in return. Metal in the filter. Rail pressure that swings or won’t hold. Also bad injectors dump extra fuel, drive soot, and clog the DPF even if the turbo is healthy.

How we find it. We scan the ECM, watch rail pressure, timing, and balance rates. We check lift pump supply, suction vacuum, filters, water separator, and tank venting. Leak-down and return tests expose weak injectors or a relief valve. D13 lines and cups get a close look.

How we fix it. Filters and lift pumps replaced. Lines and seals repaired. D13 cups resealed or replaced. Tested injectors or a quality reman pump when needed. System flushed, injectors coded if required, learns cleared, and a loaded road test. Keep it healthy with on-time filters, clean fuel, and quick leak fixes. We service Volvo D13 and Cummins ISX or X15. We explain options and back the work.

Fuel System Repairs

Road Test And Data Scan

We drive it under load, pull active and stored codes, and watch rail pressure, commanded vs actual, balance rates, temps, and smoke. This sets the baseline.

Supply And Suction Test

We measure lift-pump flow and pressure, check suction vacuum from tank to filters, and find air leaks, collapsed lines, or a plugged pickup. Any restriction starves the pump.

Filters And Water Separator

We inspect and replace clogged elements, drain water, and check fuel quality. Cut-open filters show debris or metal that points to pump or injector wear.

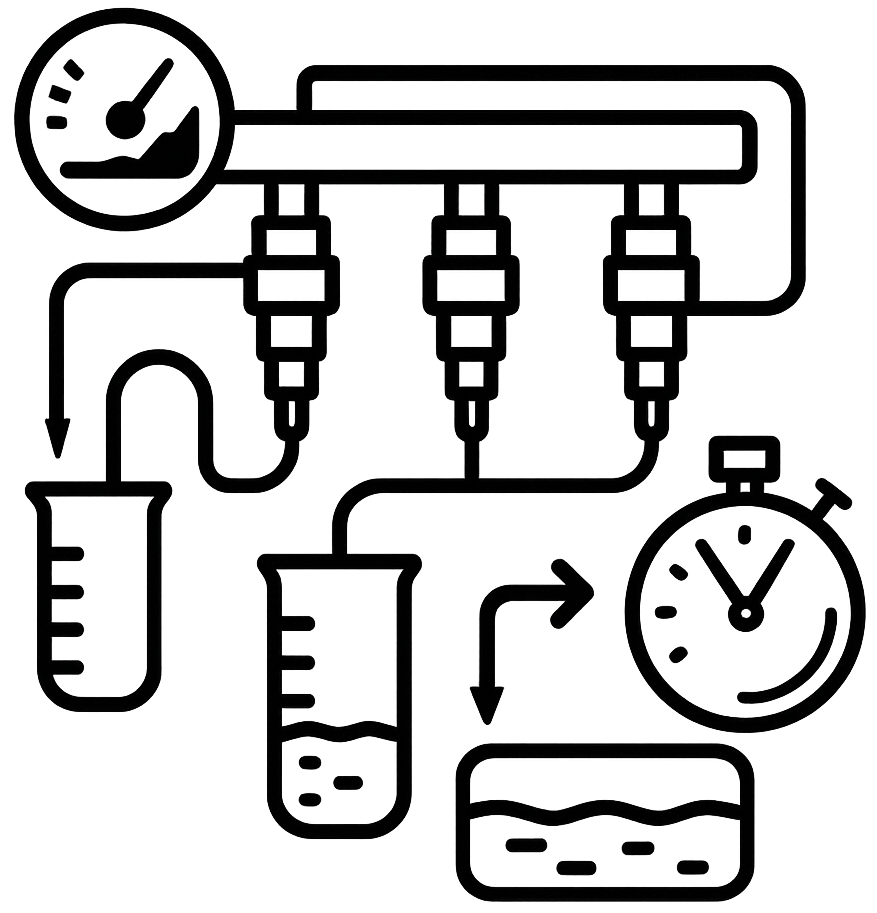

Return And Leak-Down Tests

We measure injector and rail-relief return rates and hold rail pressure to see where it bleeds off. This isolates a weak injector, leaking valve, or D13 cup issue.

Injectors Or High-Pressure Pump

We install tested injectors, reseal or replace D13 cups, or fit a quality reman high-pressure pump when needed. Lines and seals are renewed and torqued to spec.

Final Calibrations And Road Test

We code injectors where required, clear learns, verify rail pressure and balance under load, and check smoke and temps. You leave with clean data and strong pull.

Fuel System Service. What You Should Know

What’s Included in Fuel Service

Road test under load. We scan the ECM and watch rail pressure (commanded vs actual), balance rates, temps, and smoke to set a baseline.

Measure lift-pump flow and pressure. Check suction vacuum from tank to filters and find air leaks, collapsed lines, or a plugged pickup.

Inspect/replace clogged elements, drain water, and check fuel quality. Cut-open filters reveal debris or metal that points to pump or injector wear.

Measure injector and rail-relief return and hold rail pressure to see where it bleeds off. Isolates weak injectors, leaking valves, or D13 cup issues.

When You Should Bring It In

Slow pull on hills, long crank hot or cold, rough idle, or rail pressure that won’t hold.

Black or white smoke, strong fuel odor, or visible air in the return line.

Dirty filters, water in the bowl, or metal flakes when we cut them open.

High EGTs and frequent regens often trace to fueling faults or dripping injectors.

Why It Matters

Faulty or over-fueling injectors spike soot and will clog the DPF fast. Early fixes prevent cylinder wash and pump damage.

Healthy supply, sealed lines, and good injectors bring steady rail pressure and cleaner burn.

Root-cause repairs stop the same issue from taking out injectors or the high-pressure pump again.

Small fixes beat tow bills and full replacements. Do fuel filters on time in your PM service.